VFFS Machines Leading the Way !

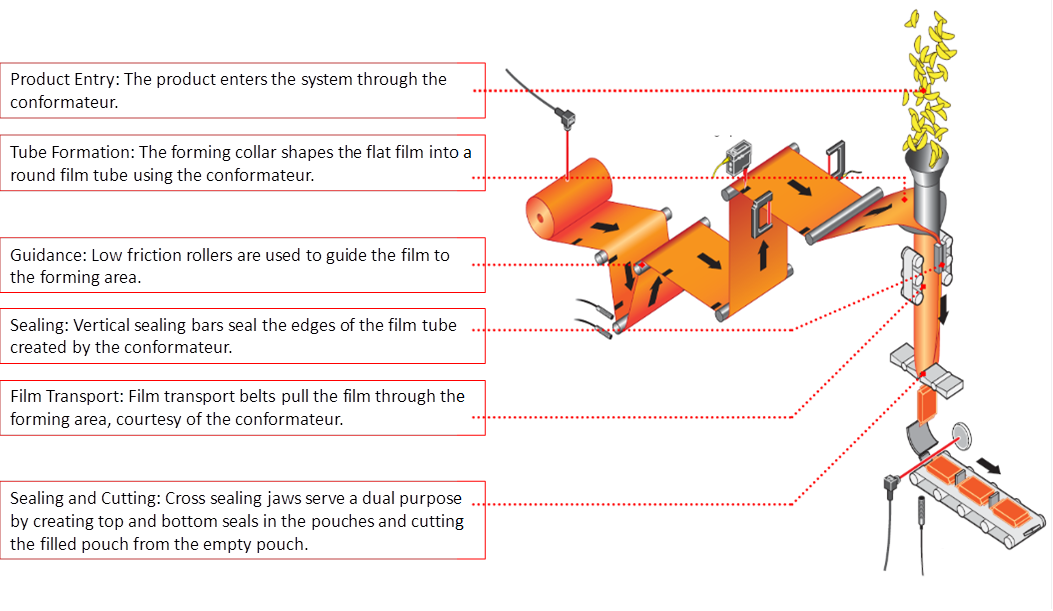

In the intricate world of medical device packaging, precision, hygiene, and regulatory compliance are paramount. VFFS (Vertical Form Fill Seal) machines have emerged as indispensable tools in this field, offering a suite of capabilities tailored to the needs of the medical devices industry. As VFFS manufacturers, we take pride in our commitment to excellence, exemplified by our 21 CFR Part 11 compatibility, capability to use TYVEK film for sterile product bagging, advanced feeding technologies, and qualification up to ISO 6 level of cleanliness.

21 CFR Part 11 Compatibility: A Regulatory Cornerstone

Adherence to regulatory standards is non-negotiable in the medical devices industry. Our VFFS machines stand out by offering 21 CFR Part 11 compatibility, a pivotal regulation that governs the use of electronic records and signatures in manufacturing and packaging processes. This compatibility ensures data integrity, security, and compliance, mitigating the risk of regulatory issues and assuring our customers of a seamless path to compliance.

The Calibration Process: Ensuring Sealing Perfection

In the realm of medical device packaging, precision and consistency are paramount. To ensure that each bag meets the stringent standards required for sterility and product integrity, a comprehensive process for qualifying sealing is essential. This process involves the calibration of all critical parameters, such as jaw pressure, sealing duration, temperature control, and more, each time the Vertical Form Fill Seal (VFFS) machine produces a bag.

1. Pressure Calibration

2. Duration Calibration

3. Temperature Control Calibration

TYVEK Film Capability: Preserving Sterility with Precision

Maintaining sterility throughout the packaging process is a critical concern when handling medical devices. Our VFFS machines excel in this regard by offering the capability to use TYVEK film. TYVEK, composed of high-density polyethylene fibers, boasts exceptional strength, tear resistance, and microbial barrier properties. With our VFFS machines, you can confidently bag sterile products, safeguarding them against contamination during the packaging journey.

Feeding Technologies: Tailored Precision

The heart of any VFFS machine lies in its feeding mechanism, which determines how products are loaded into the packaging. We provide versatile feeding technologies that cater to the diverse needs of the medical devices industry.

Weighting Technologies:

-

Vibrating Rails: Our VFFS machines are equipped with vibrating rails, using controlled vibration to align and feed products accurately. This method is ideal for products requiring precise weight measurements and consistent positioning within the package.

-

Multihead Weighers: For those dealing with a range of medical devices with varying weights and shapes, our VFFS machines feature multihead weighers. These advanced systems employ multiple vibrating hoppers to achieve high-speed and high-accuracy product dispensing.

Counting Technologies:

-

Vibrating Bowls: When counting smaller medical devices like tablets or capsules, our VFFS machines integrate vibrating bowls. These bowls use vibration to orient and count the products before they are smoothly fed into the packaging process.

-

PLC (Programmable Logic Controller): For precise counting control, our VFFS machines employ PLC-based counting systems. These systems can be customized to count a specific number of products, ensuring accurate packaging.

ISO 6 Cleanliness Certification: Elevating Hygiene Standards

In the pursuit of excellence, our VFFS machines are certified to operate within ISO 6 cleanroom environments. ISO 6 (Class 1,000) cleanrooms maintain stringent limits on airborne particle concentrations, crucial for industries where contamination can have severe consequences. By adhering to these cleanliness standards, our VFFS machines contribute to the production of safe, sterile medical devices by minimizing the risk of contamination.

Conclusion: Pioneering Precision and Hygiene

As VFFS manufacturers, we understand the unique challenges and requirements of the medical devices industry. Our commitment to excellence is reflected in the 21 CFR Part 11 compatibility, TYVEK film capability, advanced feeding technologies, and ISO 6 cleanliness certification integrated into our VFFS machines. These features empower our customers to package medical devices with unparalleled precision, hygiene, and compliance, ultimately ensuring the safety and well-being of patients worldwide. With our VFFS machines at the forefront, the future of medical device packaging is aseptic, efficient, and precise.